Contact Patch Longitudinal Compliance – Suspension KPI

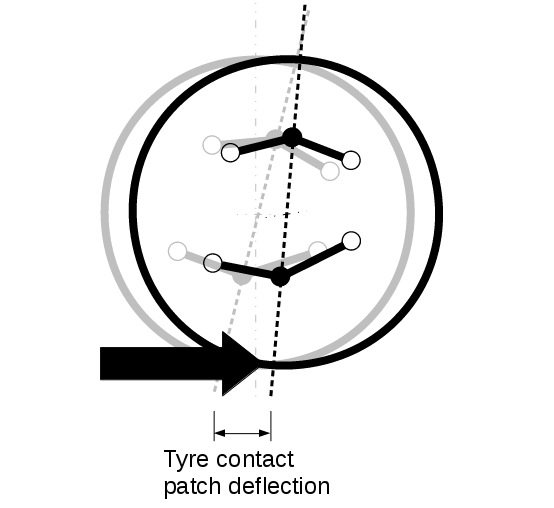

Contact patch longitudinal compliance (or its inverse, contact patch longitudinal stiffness) is a metric which measures the deflection of the tyre contact patch to a longitudinal braking force. The metric is reported in millimetres of suspension deflection per Kilo-Newton of braking force, mm/kN.

Contact patch longitudinal compliance is a metric used to understand the compliance in a suspension system under braking. Lower contact patch longitudinal compliance (e.g. higher contact patch longitudinal stiffness) on a suspension contributes to improved brake ‘feel’.

As with many suspension characteristics, there is a trade-off to delivering low contact patch compliance. On most suspension system layouts (e.g. double wishbone, MacPherson strut), contact patch longitudinal compliance is inherently linked to wheel centre longitudinal compliance. In cases where vehicle ride and impact performance is important, the suspension designer would like to have high wheel centre longitudinal compliance. This improves impact performance as the longitudinal compliance at wheel centre helps to absorb some of the energy of an impact and reduces the energy transmitted to the vehicle body. The trade-off is that high wheel centre longitudinal compliance means even higher contact patch longitudinal compliance. This is due to the wheel centre to tyre contact patch lever arm (i.e. the tyre radius) to a braking force at the tyre contact patch. This lever arm causes a castor ‘wind-up’ of the suspension under braking. The resulting contact patch longitudinal compliance is a combination of the wheel centre compliance and castor wind-up. As a result, brake feel is often compromised on production vehicles in the interest of good impact performance and passenger ride comfort.

It was noted above that most suspension systems have the inherent link between wheel centre longitudinal compliance and contact patch longitudinal compliance. One suspension layout which minimises the trade-offs between these metrics is the integral link suspension system. This system allows the suspension designer to deliver high wheel centre longitudinal compliance without excessive contact patch longitudinal compliance. It does this by controlling castor ‘wind-up’ under braking. The integral link suspension system is an expensive system to develop and produce and as a result is usually only found on premium production vehicles. The integral link suspension will be discussed in detail in a future post.

RACE reports both contact patch longitudinal compliance (mm/kN) and contact patch longitudinal stiffness (kN/mm).

—

ENHANCE YOUR CHASSIS AND SUSPENSION SYSTEMS EXPERTISE WITH CUTTING-EDGE SOFTWARE SOLUTIONS AND SUSPENSION COURSES

AUTOMOTIVE/MOTORSPORT SUSPENSION AND CHASSIS SYSTEMS – DESIGN AND ENGINEERING FUNDAMENTALS COURSE

SUSPENSION PERFORMANCE TUNING USING MULTIBODY SIMULATION SOFTWARE COURSE

START USING RACE SOFTWARE TODAY WITH A FREE TRIAL ON ALL PLANS